“Neoprene Flex Conductive”

“Urethane Flex Static Dissipative”

Screw Clamps

What Is the Meaning of Static Buildup?

Static buildup refers to the event when electrical charges are exchanged between the surfaces of two objects as they rub together. When the surfaces of objects are rubbed together, the electrons are transferred from one material to the other, and when they get separated, one object takes on a positive charge and another with a negative charge, and the space between the two charges generates static electricity. The most common cause of static buildup can be boiled down to factors, such as type of material, climate, and amount of repetitive contact. However, three major types of static buildup can occur: contact, frictional, and detachment. Contact static buildup is one of the simplest and the most frequent causes of static electricity because an electrical charge is generated when two objects encounter each other, exchange electrons, and create static electricity by separating. Like contact static buildup, frictional static buildup is when two abrasive objects come into contact with one another and make an electric charge when they rub together and separate. However, the surface area that generates the energy is much larger due to the abrasive nature of the materials. Detachment static buildup is when two materials are already in contact with one another, and a charge is generated when the surfaces are separated. While static electricity is often generated on a minuscule scale, it is amplified when dry air is introduced because it is a natural conductor. Static electricity is not an issue of concern for most people, as static buildup usually ends up as a mild shock. However, it is a concern in industrial facilities where workers must transfer large volumes of dry materials using industrial machinery and flexible hoses, and depending on the type of application, it could potentially cause significant problems from explosions to short-circuiting machinery.

Why Is Static Electricity Harmful to Equipment?

If enough static electricity has been built up and generated, it could generate electrostatic sparks and produce a sudden flow of energy that can cause damage to electronics and short-circuit your machinery’s components and systems. This disruption to the machinery’s components can disrupt the production process and cause a chain reaction of problems that could result in catastrophic system failure for industrial facilities. While static electricity is a harmless nuisance to people, it can become a severe hazard to equipment, depending on the circumstance. Due to this possibility, many industrial facilities utilize methods to prevent static buildup from occurring. Raising the humidity, for instance, is one of the many ways to neutralize a static buildup because the water particles in humid air will break up static charges quickly. Some facilities even install conductive flooring, anti-static hoses, and require workers to wear protective clothing to prevent static discharge, especially when handling flammable materials such as grains, wood dust, and debris. However, one of the best ways to deter static buildup is by utilizing anti-static hoses to prevent any electrostatic buildup when materials are being transferred from one point to another.

How To Measure Ductwork

What Are the Causes of Static Electricity in Manufacturing?

One of the leading causes of static electricity in manufacturing is the transfer of abrasive materials. As materials are being transferred in large volumes through ducts and flexible hoses, the materials constantly come into contact with one another. If the friction of the material has generated enough static, it can create an electrical spark that can either send currents of energy to the machine’s system or ignite the material and cause a massive fire and explosion. While the latter depends on the transferred material being flammable by nature, industrial facilities such as grain handling, wood and metal workshops, and plastic manufacturers are more prone to cause these kinds of incidents. So, these industrial facilities utilize a static dissipative hose to control static buildup in a factory setting. An anti-static hose is a type of flexible ducting specifically designed to dissipate electrical buildup when abrasive materials are transferred. These flex hoses ensure the safety of industrial workers by preventing static-related incidents and serve as a reliable means to transfer abrasive materials safely without incident. However, it is essential to note that anti-static ducts can only prevent static discharges from accumulating within the ductwork, and it does not account for any exterior electrical discharges, so industrial facilities need to employ additional safety measures that eliminate as many ignition sources and exposures as possible to prevent any electrostatic-related explosions.

Screw Clamps

What Material Is Anti-Static?

A variety of static dissipative materials can be used to prevent electrical buildup such as conductive polymers, carbon-based materials, and metal-based coatings are anti-static by nature and can dissipate the energy of the static charge. As a result, any of these materials can be turned into viable flexible ducts specifically designed to transfer materials and dissipate electrical charges. So, materials such as polyurethane and neoprene are excellent instances of anti-static hose materials that can be used to create static dissipative tubing and conductive ducting. It is essential that you utilize conductive flex hoses made from static dissipative material to prevent a static charge from accumulating. On the other hand, incorporating a conductive coating into a static dissipative hose allows the generated electrostatic energy to discharge and escape as abrasive materials are continuously transferred. Considering how many industrial facilities are surrounded with flammable materials, sudden sparks from static buildups pose a severe threat to every industrial facility, and using a conductive hose in every applicable way can significantly reduce the possibilities of static-induced incidents.

“Neoprene Flex Metal Free”

- Completely non-metallic and non-magnetic

- Non-metallic polyethylene rod helix eliminates sparking and resists corrosion & permanent deformation

- Lightweight and flexible, easily ovalizes for installation in tight places

The “Neoprene Flex Metal Free” duct hose is a specialty made hose recommended for industrial air movement and fume control applications that require a completely metal-free product. The black flexible ducting is constructed using single-ply neoprene coated polyester fabric. The flex hose is then reinforced with a spiral Polyethylene rod helix that gives the hose its flexibility without sacrificing its shape or rigidity. Polyethylene has a high load bearing capacity and excellent tear resistance. It is also abrasion, oil, and solvent resistant, with a high resistance to sunlight and weather conditions.

As a result of the Polyethylene rod instead of a standard metallic helix, the metal-free flex hose is rendered non-magnetic and cannot be affected by any type of magnetic field. The non-metallic polyurethane rod helix design eliminates sparking and is resistant to corrosion and permanent deformation. Unlike metal, if some weight is applied to the exterior of the hose, the polyethylene rod has the ability to bounce back. In addition, the commercial hose is lightweight, flexible, and easily forms an oval shape for installation in tight spaces. The duct hose offers both efficient flow characteristics and excellent abrasion resistance.

“Neoprene Flex Conductive”

“Urethane Flex Static Dissipative”

Using “Neoprene Flex Conductive Static Dissipative” to Reduce Static Buildup

Static buildup occurs when materials are moved from one source to another, therefore this static buildup can be avoided by using static-dissipative hose and ducting. When it comes to reducing static in your machinery, utilizing anti-static ducts such as the “Neoprene Flex Conductive Static Dissipative” hose is one of the best and most assured ways to reduce static buildup. Made from a double-ply polyester fabric, the “Neoprene Flex Conductive Static Dissipative” hose is coated with neoprene and a conductive elastomer that significantly reduces the danger of static buildup by allowing the energy to escape. Neoprene is a synthetic rubber with natural static resistance properties, making it perfect for an anti-static hose. The flexible hose is reinforced with a spring steel wire helix and, as a result, exhibits tensile strength and crush resistance, making it great for industrial facilities that require durability in their flexible hoses. Aside from abrasive resistance, the “Neoprene Flex Conductive Static Dissipative” hose even showcases resistance towards chemicals and extreme temperatures ranging from -40 to +250 degrees Fahrenheit. By utilizing anti-static hoses and static dissipative ductwork, you ensure the safety of industrial facility workers and the machinery’s electrical components daily.

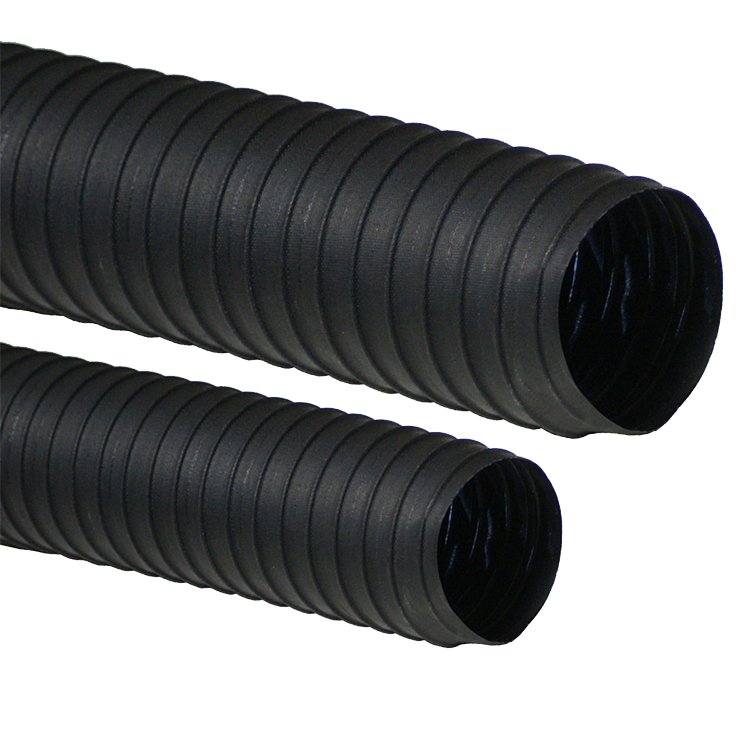

“Neoprene Flex Conductive”

- More durable than double-ply cotton hoses

- Surface Resistance Level: 103 to 105 Ohms/Square

The “Neoprene Flex Conductive” static dissipative hose is recommended for industrial air movement, fume control, dust control, and light bulk material handling applications. The flex ducting is made from double-ply, neoprene coated polyester fabric that has been coated with a conductive elastomer. Flexible ducts with higher conductivity help reduce the danger of static buildup by allowing any electrostatic buildup to escape. If the net charges grow faster than a material can dissipate them, an electrostatic charge builds up. The excess charge can suddenly neutralize by a flow of charges to the surroundings, known as an electrostatic discharge or static spark. By super-heating the surrounding air and causing it to rapidly expand, the discharge is both visible and audible.

The neoprene coating of the hose material offers excellent abrasion and chemical resistance and is designed for abrasives, air, dust fumes and other materials. Each commercial hose is reinforced with a spring steel wire helix for good crush resistance and tensile strength. This product can handle both positive and negative pressure, please refer to the hose specification sheet for test data on specific sizes. This static dissipative hose has a working temperature range of -40 to +250 degrees Fahrenheit.

Is Polyurethane Hose Material Anti-Static?

A type of polyurethane film is another excellent material for static dissipation and flexible ducts, such as the one used to build the “Urethane Flex Dissipative” hose. This hose is perfect for applications that specifically aim to prevent static-induced explosions and accidents. As polyurethane is used in a diverse range of products and applications, the material stands as incredibly abrasions resilient and material that can be customized and altered to suit a variety of needs. Take note that not all PU materials are static dissipative!

Featuring an electrostatic discharge-resistant surface, the “Urethane Flex Dissipative” hose discharges any static buildup within the anti-static duct. The medium-weight flex hose is ideal for medium-duty applications that involve dust, materials, and abrasives and is made from FDA-approved materials, which makes it suitable for agricultural and grain handling facilities that require static dissipation. The flex hose is designed with excellent flexibility and can function in extreme temperatures ranging from a low -65 to a high +225 degrees Fahrenheit, making it extremely useful in harsh and demanding environments. However, it is essential to note that different colors are made from other materials and will ultimately affect how you utilize this anti-static hose in your applications.

“Urethane Flex Static Dissipative”

- Great abrasion resistance & high tear strength

- Ideal for clean room and material plastic processing applications

The “Urethane Flex Static Dissipative” material handling hose is a medium-weight wall hose featuring an electrostatic discharge resistant surface. The electrostatic resistant surface allows this product to reduce static buildup when handling materials. This is especially useful in applications when static buildup can result in explosions or accidents. In addition to the static resistant surface, the polyurethane used in this product gives it excellent chemical and abrasion resistance and high tear strength. The spring steel wire helix provides extra support and durability. These flex hoses are built with a medium weight construction, making it ideal for medium-duty applications with abrasives, dust, and materials. This flex duct is great for woodworking and grain handling applications.

The “Urethane Flex Static Dissipative” material ducting hose is constructed to work in a wide range of temperature applications. This product is designed to work in temperatures ranging from a low of -65 to a high of +225 degrees Fahrenheit. The high temperature tolerance, electrostatic discharge resistance, chemical resistance, and tear strength qualities given by the hose materials make this a great flex duct for most abrasive environments.

Bridge Clamps

“Neoprene Flex Metal Free” Duct

As previously mentioned, neoprene is a great material that doesn’t allow electrical charges to accumulate from within the flex duct. However, depending on your machinery, you may require a flex duct that has a metal-free design to prevent any possibility of electrical discharges from occurring altogether. For instance, the “Neoprene Flex Metal Free” is a fantastic flex duct that caters to machinery and applications requiring a metal-free duct. The flexible duct is made from a single-ply neoprene coating and is reinforced with a spiral polyethylene rod helix. While polyethylene can harbor an electrical charge, an anti-static agent can be applied to counteract this and create a sturdy anti-static duct. With its non-metallic design, the flexible duct is entirely lightweight and flexible, which makes it perfect for installation in tight and hard-to-reach places. Despite its lightweight design, the “Neoprene Flex Metal Free” offers exceptional abrasion resistance and can transfer various abrasive materials and debris, assuring its users that the duct is just as sturdy as its conductive ducting counterparts.